SK6,000 SCHEDULED TO START PRODUCTION IN Q3 2022

Investing in the world’s future; a next generation electric crane for next generation wind farms.

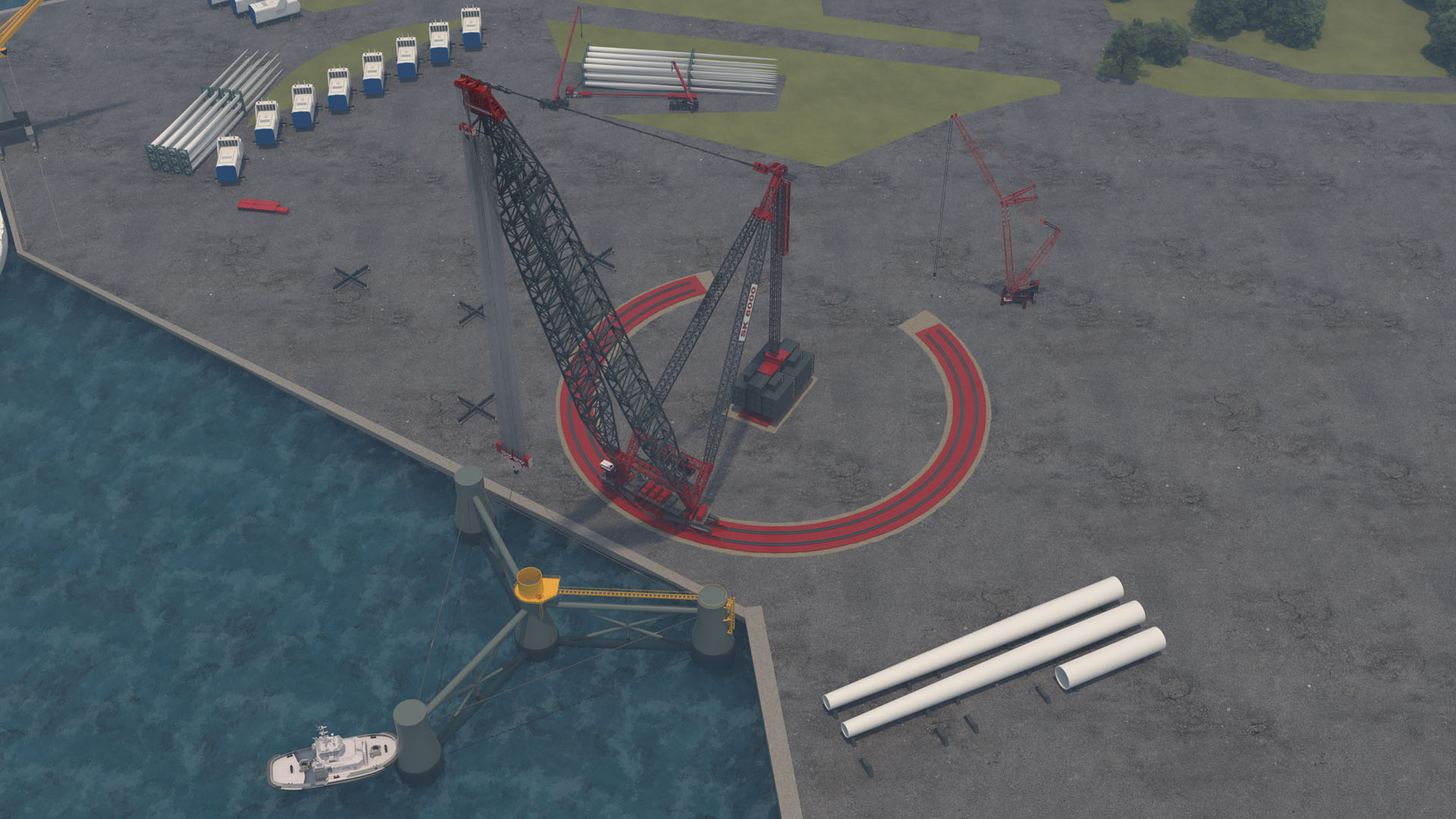

The SK6,000 ring crane has been scheduled to begin production of its long lead time components starting Q3 2022. It will allow offshore wind projects to take place under entirely electric power – even where there is no connection available to the grid.

As developers look to supply more cost-effective energy to consumers, offshore wind farms are moving to deeper waters and reaching higher to find stronger flows. As a result, the scale of turbine and foundation components – in both fixed and floating offshore wind – continues to grow.

Bottom fixed jackets and monopiles weighing between 2,000t and 3,000t are now common, while next generation turbine towers between 15MW and 20MW will rise beyond 150m. If global installed capacity targets are to be realized, the supply chain must also grow.

That is why Mammoet is investing in the SK6,000: the next evolution in the SK series of super heavy lift cranes. It will serve the needs of both fixed-bottom and floating offshore wind.

For fixed-bottom projects, when loading-out 3,000t jacket foundations in areas of high tidal range where RORO transfer is not always possible, or installing complete towers and nacelles of 20MW turbines, the SK6,000 creates maximum value onshore prior to installation at sea.

For floating wind projects, due to its a maximum radius of 144m, the SK6,000 can lift a heavy floating foundation directly into the water and assemble its turbine from a single position. This turns the quayside into a highly efficient production line.

With a maximum hook height prepared for next generation 20MW turbines and a capability to lift 6,000t, the SK6,000 will be the largest and strongest land-based crane in the market. The flexibility and scalability of the SK design enables Mammoet to grow in real-time with the changing needs of its customers, thereby futureproofing developments and advancements in the segment.

As it is containerized, the SK6,000 can be mobilized to any port, allowing projects to be executed where the right knowledge and skills are abundant, and where high-value assets can be best utilized.

With hub heights continuing to grow, the SK6,000 offers a truly commercial-scale, carbon-free solution, delivering factory efficiency with next generation capacity that others simply cannot match. And by using Mammoet’s electric-powered SPMT, the entire heavy lift and transport scope can be completed, fully emissions-free – at any location, worldwide.